In the United States, about one-third of our energy is used for industrial purposes. The good news is that today, industrial energy usage is more efficient than ever before. Over the past 30 years, the amount of energy used to produce $1 worth of goods has been cut in half.

Still, there’s room for improvement. And whether you’re a manufacturer who’s looking to save the planet or cut your monthly energy bill, efficiency is worth looking into.

Last fall, a group of PhDs, grad students and professionals from San Diego State University’s Industrial Assessment Center descended on our plastic manufacturing plant in Ontario, California. They spent a day poking around our facility, making observations, and taking measurements and notes. They then left with a stack of data to process.

In February, they delivered a 52-page master report to my inbox, complete with their findings and recommendations for improvements. The bottom line was that even in a relatively efficient facility, they found opportunities to reduce our energy consumption in ways that could save an estimated $17K in annual energy and maintenance costs.

Not every manufacturing facility has access to a team of PhDs from SDSU. So, I thought I’d share our report’s key findings that could be broadly applicable to other manufacturing facilities.

A Head Start: Some Ways in Which We Were Already Efficient

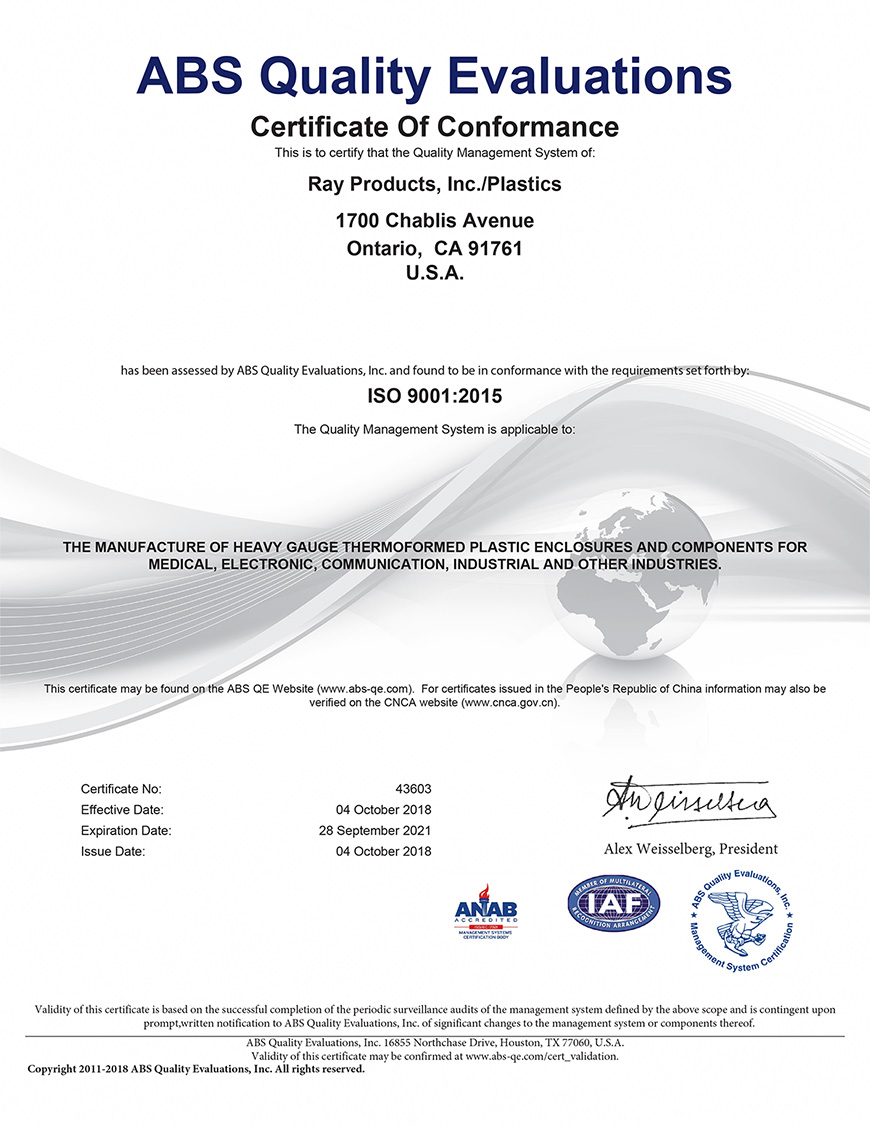

Our facility had several efficiency advantages to build on. We’re a heavy-gauge thermoformer that just celebrated our 70th anniversary. When we moved into our current plant in 1995, it was purpose-built for our needs, and we had 46 years of experience to build on.

As a result, we were able to build a plant that was very efficient from the get-go. Our layout is optimized to minimize material transport and distance traveled, as well as maximize venting; it also allows for as much process efficiency as possible. Our more recent investments in automation, robotics and other new technologies have enabled us to further improve that efficiency while adding new services to our plant.

Beyond these base-level efficiencies, our SDSU assessment also called out the efficient use of lighting and reflectors, organization and layout, and focus on safety — which result in process and energy efficiency.

But, even with these efficiencies already in place, we still found plenty of room for efficiency advancements.

Lighting: Rapid Advancements in Efficiency

We’re not new to energy-efficient lighting. About a decade ago, we replaced our old HID lighting with (then) state-of-the-art high-efficiency T8 fluorescent lighting. But, LED lighting technology has matured significantly since then. Our SDSU engineers estimated that, by retrofitting our existing fluorescent fixtures with LED lighting, we could move from 175 watts per fixture to 90 watts per fixture.

In their estimation, that retrofit could save our facility nearly $8K per year in combined energy and maintenance savings, and be implemented with a cost of just under $10K.

That’s a deal that I think any facility would take. With our assessment’s math, the upgrade would pay for itself in a little over a year. So, we decided to move ahead with their recommendations.

That’s when we ran into a bit of a challenge. While our SDSU team had believed that we could keep our existing fluorescent fixtures and use a retrofit kit to convert them into LEDs, the lighting contractors whom we talked to found that our specific fixtures weren’t compatible with retrofit kits.

As a result, our upgrade would need to completely replace our existing fixtures, which increased the combined labor and lighting cost by a factor of 3–4x.

This made us change strategy just a bit. We’re still planning to upgrade our fluorescent lighting to more efficient LEDs, but instead of performing the upgrade immediately, we’re going to hold off for a bit. As our fluorescent lighting nears its expected end of life and maintenance costs climb over the coming years, we’ll see a higher ROI from a wholesale replacement. It’s also likely that in that time, LED efficiency will continue to increase while costs come down.

Instead of relamping our fluorescent fixtures when that time comes, we’ll roll those costs into their wholesale LED replacement.

In the meantime, we’ve followed the study’s other lighting-related recommendation: installing occupancy sensors throughout much of our facility. There’s no more efficient light than one that’s turned off, and these sensors will help to ensure that we’re not burning energy to illuminate unoccupied parts of our facility.

Key Lighting Takeaways

Even if you’ve invested in energy-efficient lighting in the past, it’s likely that newer, more efficient lighting technologies and intelligent lighting controls are available today. Work with your utility or a qualified lighting contractor to assess the cost and benefits of a lighting upgrade.

Machinery: The Benefits of Premium-Efficiency Motors

Electric motors account for about 40% of all energy consumption in the U.S. In 2016, the Department of Energy launched new “NEMA Premium” efficiency standards for electric motors.

While the savings of a premium-efficiency motor vary with load and operating hours, replacing a single 100-horsepower standard motor with a premium-efficiency motor could generate nearly $3,000 in annual energy savings.

We use a range of electric motors in our manufacturing operations, with ratings of between 3 hp and 100 hp. Our SDSU assessment estimated annual energy savings of about $3,800 if we replace them all with premium efficiency motors.

The SDSU assessment recommended that we wait until the existing motors are due for replacement to perform this upgrade. If we consider the total cost of just going in today, ripping out our functioning standard-efficiency motors and putting in premium-efficiency replacements, it would take a decade or more to pay for that upgrade.

By timing our upgrades to coincide with the timing of motor replacements, the cost of this efficiency upgrade is simply the cost of a premium-efficiency motor, minus the cost of a standard-efficiency motor.

With that plan of action, our assessment estimated that our premium-efficiency motor upgrades would pay for themselves with energy savings in about 2.5 years.

Key Machinery Takeaways

Assess the efficiency of your existing motors. If they’re standard-efficiency or the older “NEMA Energy Efficient” designation, plan to replace them with premium-efficiency models at your normal replacement interval, or when you experience issues with your current equipment.

Compressed Air: More Efficient Production, Use and Storage

The U.S. Department of Energy estimates that compressed air systems account for 10% of the energy used in this country’s manufacturing. Our facility uses a 100 hp compressor (with another for backup) to power pneumatic drills, sanders, grinders and blow guns used throughout our manufacturing processes.

Our SDSU assessment made four recommendations related to improving the efficiency of our compressed air system. We’ll be following two of those recommendations and bypassing the other two.

Leak Reduction

Anyone who’s worked with compressed air systems knows that leaks happen. Even high-quality fittings and bearings degrade over time and need to be sealed, maintained and replaced at regular intervals.

Our SDSU assessment estimated our energy costs for leaked air at a bit over $600 per year. Not a huge amount, but certainly an issue worth addressing.

It’s challenging to detect air leaks in a noisy production environment. So, on a recent Saturday morning, a team of us went into the now-quiet factory, filled up the compressed air lines, and spent a few hours finding and fixing leaks. We’ve also added this as a process on our regular maintenance schedule so that we can keep ahead of compressed air leaks going forward.

Reducing Maximum Air Settings

Our air compressor is set to maintain 110 psi, while none of the equipment that it runs requires more than 100 psi. This gives us a little bit of headroom so that if there’s a temporary spike in demand, our system pressure never dips below that 100 psi mark.

In our application, a temporary dip in pressure could result in a failed part. That’s something we work hard to avoid.

However, our SDSU assessment estimated that just dropping the max pressure of our system to 100 psi could save a bit over $1,000 per year in energy costs.

So, we’ve started to look at other solutions to maintain that headroom, with a slightly lower pressure. We haven’t completed the implementation process, but we’re moving toward adding a reserve pressure tank to our system. That will allow us to maintain pressure over spikes in demand, while earning the energy-savings benefits of an overall slightly lower system pressure.

Recommendations We Didn’t Take: Switching to Electric Tools and Brooms

Our report gave two recommendations that made sense on paper, but not for our production process.

First, the report recommended that we switch from air-powered to electric tools. Our experience is that electric tools simply can’t keep up with the power and durability of pneumatic tools in our environment. The estimated $2,400 in annual electric savings won’t make up for the loss of performance and durability.

The report also recommended that instead of having our workers clean off products, equipment and work areas with air guns, we provide them with brooms to perform the same task. In our opinion, the $1,300 in estimated savings isn’t worth the decreases in productivity and worker satisfaction.

Our Results

In all, our audit from SDSU found just over $17K in potential energy savings, with about $22K in improvement costs. The reality of our lighting options changed that math a bit, but by rolling in some maintenance costs and implementing the auditors’ recommendations over time, we expect that we’ll eventually see about $10K in energy savings, with an improvement cost that’s not too far off their initial estimates.

For a large-scale manufacturing operation like ours, that may not seem like huge savings, but over time — say, a period of three, five or 10 years — I can certainly think of things that I’d rather do with $30,000, $50,000 or $100,000 than just feed it back to the electric company.

Tools for Building Efficiency in Your Plant

While not every manufacturing plant has access to the same PhD-level audit that we did, you still have plenty of tools for increasing efficiency.

Here’s a list of resources that I’d recommend for finding and improving efficiency:

Lighting Contractor Association Searches

Our biggest energy-savings opportunity was in improving the efficiency of our lighting. There are two national organizations that focus on certification and training in this area: the National Electrical Contractors Association (NECA) and the National Association of Lighting Management Companies (NALMCO). NALMCO is smaller but more focused on lighting, while NECA is larger but allows you to search for contractors who specialize in lighting or efficiency.

http://nalmco.org

http://www.necaconnection.org/#/search/

Energy Star’s Industrial Energy Management Tools

Energy Star, the government’s energy-efficiency program, offers a range of specific tools targeted at manufacturers. These can range from certifications and recognition to tools, rebates and incentives.

https://www.energystar.gov/buildings/facility-owners-and-managers/industrial-plants

Energy.gov Industrial Assessment Centers

Our SDSU audit came out of a government program that funds Industrial Assessment Centers (IACs) at schools across the country. You can check to see if there’s an IAC near you that could perform the same type of audit that we had, and find relevant data from audits like ours performed at a variety of industrial facilities around the country.

https://www.energy.gov/eere/amo/industrial-assessment-centers-iacs

Your Utility

Electrical utilities are typically required, by law, to operate energy-efficiency programs. Many times, these rebates can pay for part or even all of the upgrade costs of new efficiency measures. It’s definitely worth reaching out to your utility to see what programs and incentives they offer that might be applicable to your facility.

Committed to Smarter Practices

We may have been in business for over 70 years, but that doesn’t make us old-school. Every item Ray Products produces is created in an efficient, state-of-the-art thermoforming facility, and we plan to keep it that way. As technologies progress to make manufacturing plants and equipment more efficient, you can rest assured that we will too. It’s simply good sense.

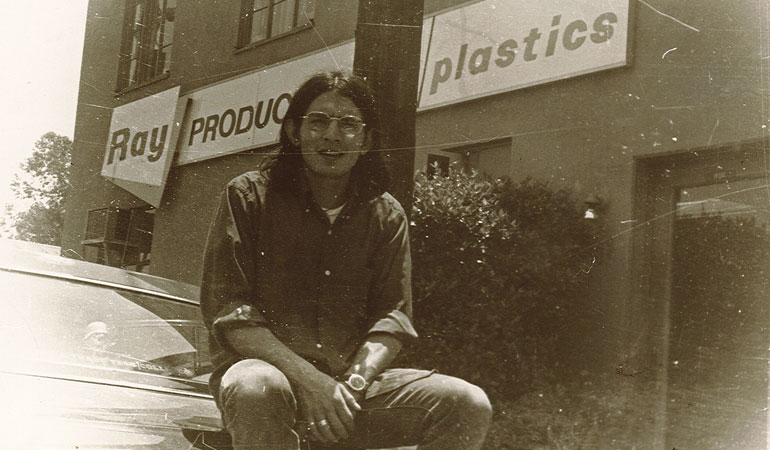

In 1968, a postage stamp cost 5¢, a gallon of gas cost 34¢, a dozen eggs went for 53¢ and a gallon of milk was $1.07. That year, Ray Products was closing in on 20 years in business, with founder Allen Ray at the helm.

In 1968, a postage stamp cost 5¢, a gallon of gas cost 34¢, a dozen eggs went for 53¢ and a gallon of milk was $1.07. That year, Ray Products was closing in on 20 years in business, with founder Allen Ray at the helm. We’ll miss Hector, but we’re excited for him and hope he gets to enjoy his retirement for many years to come – with plenty of fishing trips, visits to Mexico, and time with family and friends.

We’ll miss Hector, but we’re excited for him and hope he gets to enjoy his retirement for many years to come – with plenty of fishing trips, visits to Mexico, and time with family and friends.