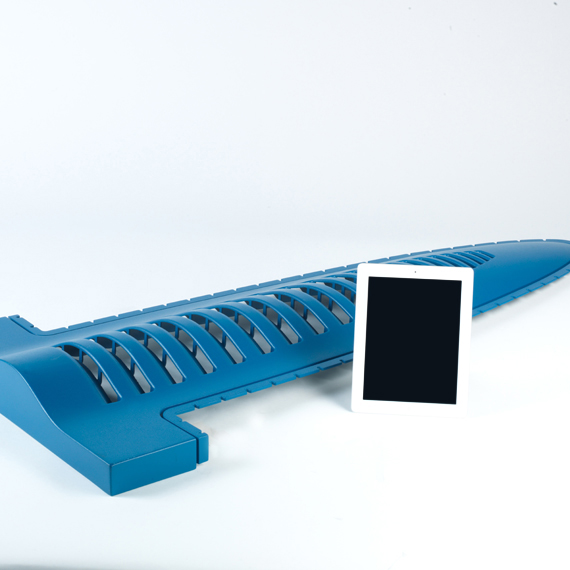

Semiconductor Testing Equipment

| MATERIAL | UL 94 V-0 Flame Rated Sheet |

|---|---|

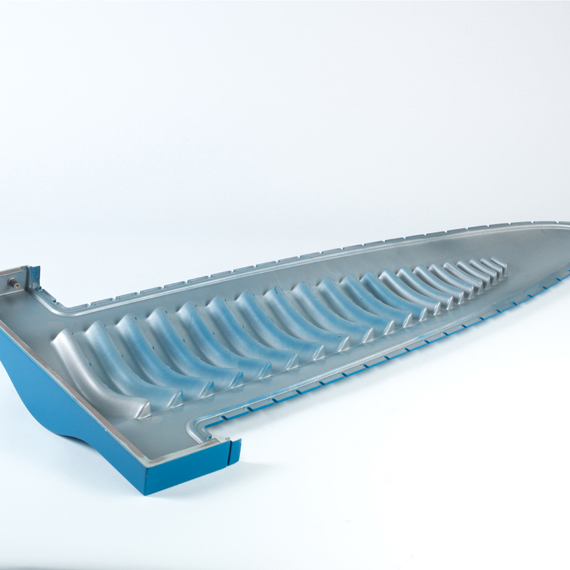

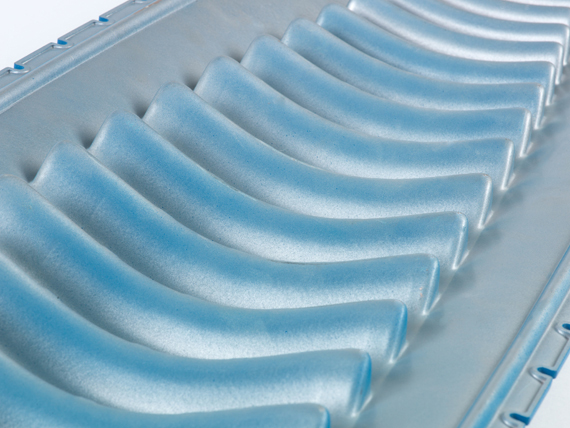

| PROCESS | Pressure Forming |

| SECONDARY OPERATIONS | Painting, Silkscreening, Hardware Installation |

| INDUSTRY | Semiconductor Manufacturing |

Project Summary

When the leading manufacturer of Automated Test Equipment (ATE) was searching for a custom molded solution, they turned to Ray Products to provide highly cosmetic and functional pressure formed parts to meet their needs. Integrating our custom molded plastic parts with a sheet metal manufacturing process, the company was able to achieve their design intent along with the functionality and performance they needed in the final product.