Know The Difference

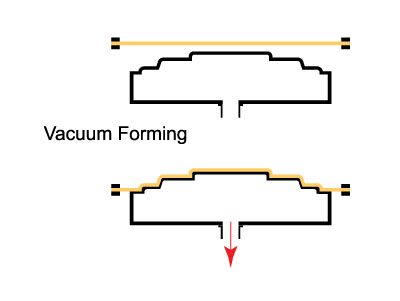

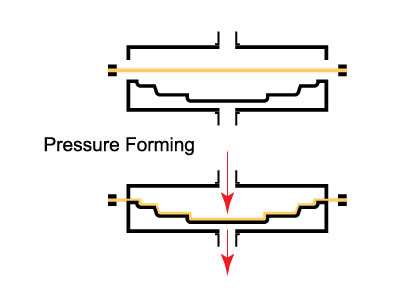

| VACUUM FORMING | PRESSURE FORMING | |

|---|---|---|

| DESCRIPTION | A sheet of plastic material is heated to pliability, then pressed against a 3D mold by vacuuming out the air between the sheet, and the mold. | A sheet of plastic material is heated to pliability, then pressed against a 3D mold by vacuuming out the air between the sheet and the mold, and applying air pressure above the plastic sheet. |

| KEY ADVANTAGES |

|

|

| PERFECT FOR |

|

|

| OFTEN USED TO CREATE |

|

|

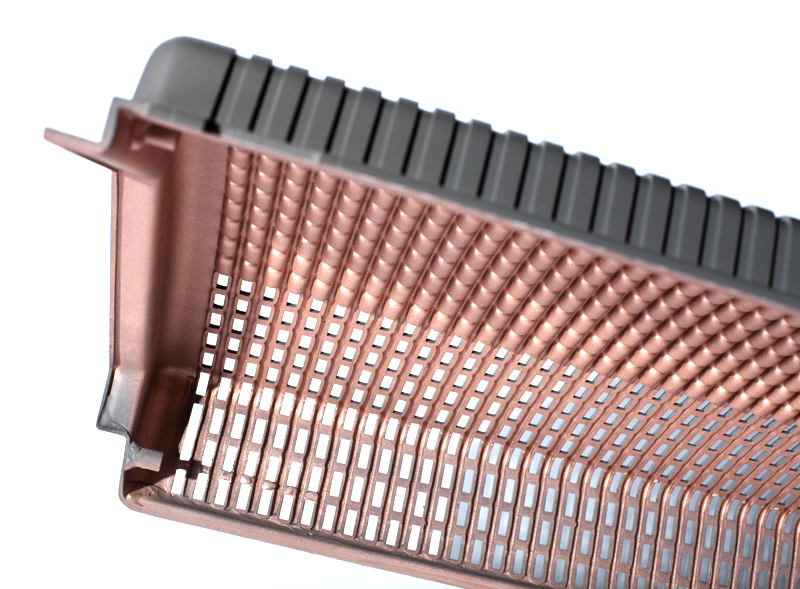

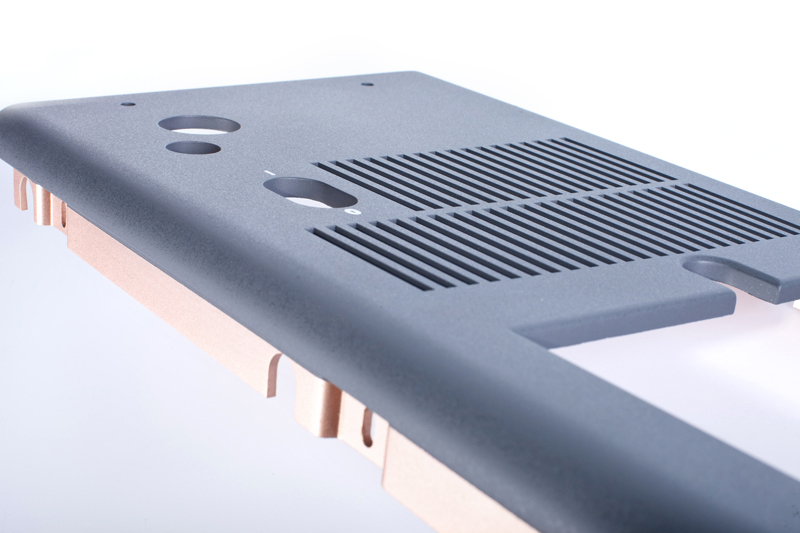

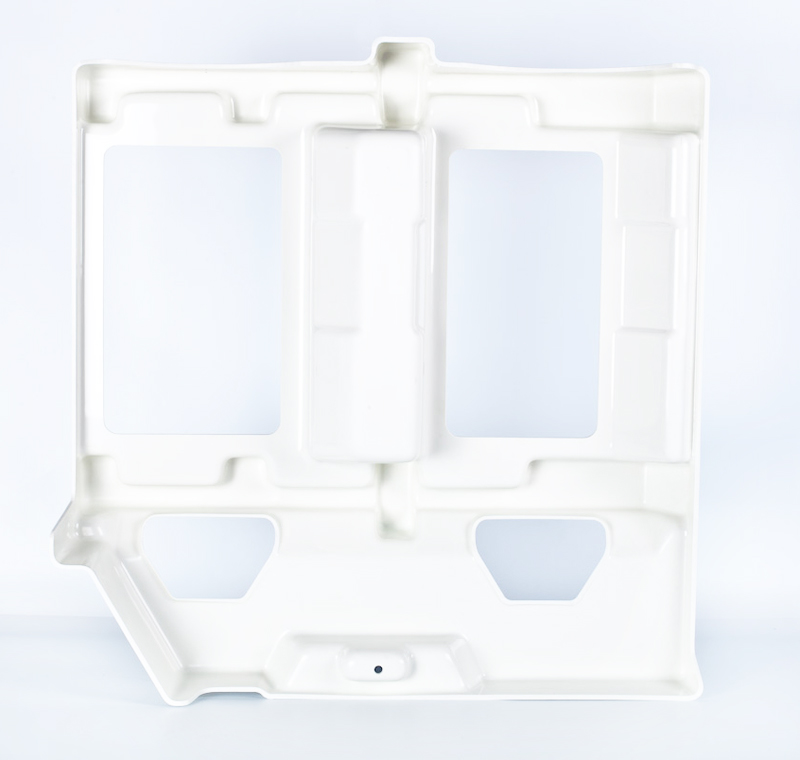

Pressure Formed Projects

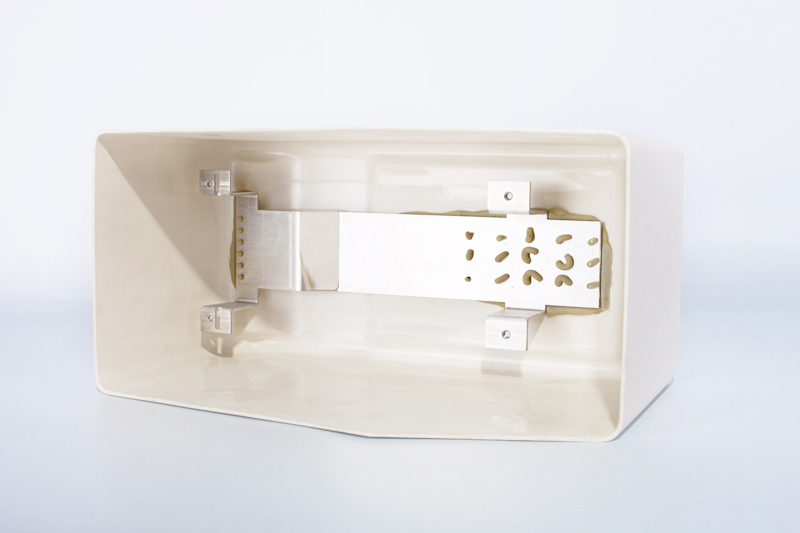

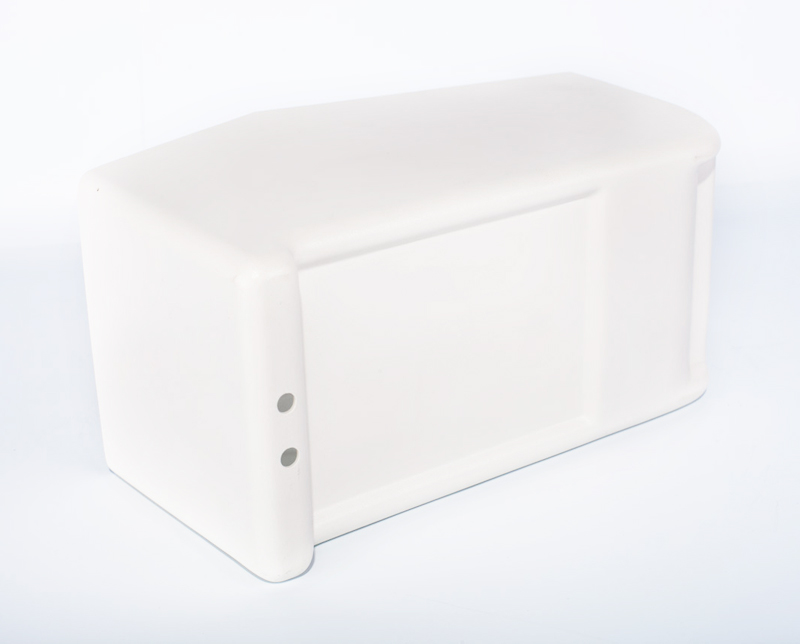

Vacuum Formed Projects